iKnife Collector

The online community of knife collectors, A Knife Family Forged in Steel

Why not a line of GEC's with a higher quality stainless steel?

I thought about the title of this discussion for a few minutes and this is what I chose. I mention this because I don't want to give the assumption what they use now is a poor quality steel at all.

The thing is there are several stainless steels that when sharpened properly can hold an edge longer than others. The only GEC knife I have now is a #68 Buckaroo with 1095 carbon blade steel. Again, nothing wrong with this steel. But I have a Spyderco with CTS-XHP (stainless). I did some extremely unscientific testing of edge retention. I cut up some pizza box cardboard with both. The XHP held an edge quite a bit longer than the 1095.

Some of the different steels can be hard enough making them more time consuming to sharpen. The remedy for this is usually more aggressive sharpening stones. Of course they aren't cheap. A few years ago I had to buy new stones when I bought knives that my old Arkansas stones wouldn't sharpen. I didn't know much about maintaining stones so they were probably just clogged and needed a good lapping. I've seen discussions about this in the past and I think the manufacturer's view is that their customer's would rather keep using the present steels instead of having blade steels they couldn't easily sharpen. I understand this completely. And speaking of cost different blade steels may drive the cost per knife high enough to keep sales down. I'm posting this thinking in the GEC group because of the quality of their knives. I'm basing my opinion of high quality on many people's reviews and the one GEC pocket knife I have owned for about 6 weeks. I like 1095. To prove that I'll continue to carry and use my new GEC knife. :) In the back of my mind I have a lack of edge retention line that if a knife crosses it I won't carry it no matter how nice the model is. I have no way to accurately test edge retention. I determine this by every day use so the performance I get may be different than someone else based on different use.

OTOH, maybe a different blade steel isn't the only answer. I understand the heat treat has as much control of blade quality as the steel itself. Maybe more. I had two knives from different companies that both had VG-10 blade steel. One knife maintained a sharp edge considerable longer than the other. I assume it was different heat treating. This issue requires more knowledge to discuss with intellegence than I have.

Most knife companies provide a wide variety of handle materials for various models. Why not do the same with blade steels? This may be a lot more difficult for reasons I can't even imagine.

One question for knife users to answer is would you rather have a knife that's very easy and fast to touch up to keep a sharp edge but doesn't hold the edge quite as long as another steel? Or would you prefer a knife that stays sharp longer and may (or may not) be more time consuming to sharpen. Again, with the proper stones any steel can be sharpened and kept sharp easily.

Any thoughts on this?

Jack

Tags:

Replies to This Discussion

-

Permalink Reply by Jack Haskins, Jr. on October 15, 2014 at 22:06

-

I can see a tiny bit of the side of the shield and it's a bit thick. Not super thin like the aluminum side of a Coke can. That may not sound like much but little things like that indicate quality in my book. If they put extra emphasis on a little thing like that I'm sure they don't skimp on important things like pivot strength and such.

-

-

Permalink Reply by Jack Haskins, Jr. on October 15, 2014 at 22:10

-

I fall into the group that like quality as well as the old timey look. Don't fit into the "younger crowd" category though. :)

Graeme said:They look nice. The 42. Big knife too. I like the chestnut, but not the 440C. Rather have 1095, and the Northfields look great with that long pull (I always like the long pull over the nail nick)

I think that by using materials like Micarta and maybe by upgrading some steel options they will pull some younger crowd in. The guys that know steel and like the modern materials but still want a "old timey" knife like their father or grandfather did. -

-

Permalink Reply by Jan Carter on October 15, 2014 at 22:12

-

Jack you are right about the pin! Please dont take your knife apart. LOL Some companies glue them in place but GEC uses a method called pinning. The back of the shield has a pin that goes through and into the scale

-

-

Permalink Reply by Jack Haskins, Jr. on October 15, 2014 at 22:18

-

Thanks Jan. I like knowing things like that.

Jan Carter said:Jack you are right about the pin! Please dont take your knife apart. LOL Some companies glue them in place but GEC uses a method called pinning. The back of the shield has a pin that goes through and into the scale

-

-

Permalink Reply by Jack Haskins, Jr. on October 15, 2014 at 22:22

-

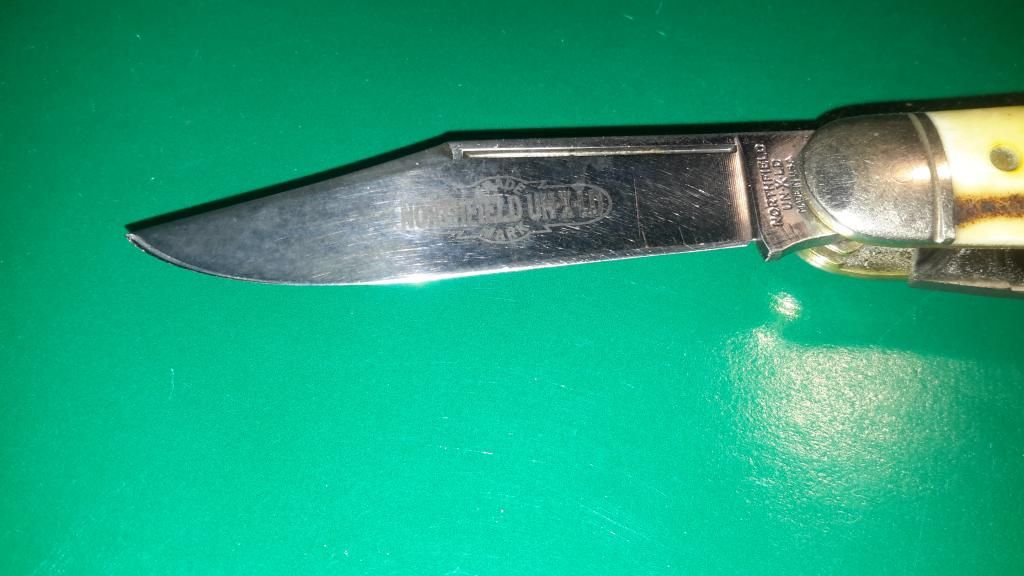

I'm sorry this is not a GEC but this is the edge I reprofiled on the knife I got yesterday. It came very sharp but I couldn't leave it alone. I lowered the angle some and put a smooth edge on it (Shapton glass 8k). Spyderco's normally come with a very toothy edge. See the tang stamp. It's CPM-M4. Don't touch your monitor. It will cut your finger. :)

-

-

Permalink Reply by Jack Haskins, Jr. on October 15, 2014 at 22:31

-

-

Permalink Reply by Gregory Warren on October 20, 2014 at 21:56

-

Jack, I couldn't agree with you more.

In the past few years I've been a collector of modern folders and tactical knives - mostly Spyderco's, Benchmade's, A.G. Russell's, with a few Mcustas, Lionsteels, Vipers, and Kershaws to round out the picture. And I can assure you that if, say, Spyderco came out with any knife in 1095 carbon steel, they wouldn't sell even one. I guess we've become steel snobs on the other side of the collector aisle.

But, really, when you consider that you can buy a ton of modern folders for less than $50, or even less than $30, all of which are made with steels which will outperform 1095 both in edge retention, and, they don't rust, it just makes one wonder what it's going to take to get the traditional folder makers to wake up and offer their wares with modern stainless blade steels.

You've got the Japanese steel makers like Hitachi along with Latrobe, Crucible, Carpenter, and Bohler making fantastic stainless blade steels so why can't we get these into the traditional folder world??

Thank goodness that Queen Cutlery (not Queen City) offers their knives in D2 steel which, with 11.5% chromium, is at least semi-stainless and is a good blade steel to boot. I also think that Queen represents one of the better values in the traditional market, but they just don't offer the variety of patterns that Great Eastern does.

I know that Schatt & Morgan's File & Wire series of knives are made with ATS-34 steel, and their Keystone series are made with 420 HC (which ain't all that great, but still better than 1095), but I've already collected all the patterns in these two lines that I'm interested in so now I'm faced with having to buy traditionals from Great Eastern in a steel which I consider to be distinctly inferior.

And as for Case knives which are made with "True Sharp" surgical stainless steel, the steel is so soft at an HRC of 54-57, that after a half dozen sharpenings, you've go no knife left - the steel is just that soft. Most people don't realize that "surgical stainless" knives are throw away knives that are disposed of after every surgery. So I would never consider buying a Case knife. They may be alright for collecting as “Safe Queens,” but I guess I'm more of a user than a collector, so I'll take a pass on Case knives.

I'm happy to see that Tuna Valley is using 154CM blade steel, but I'm not as yet so enamored of stag handles that I'm willing to pay extra $50 to $100 per knife for stag handles just to get a good blade steel. If Tuna would produce a line with less expensive ebony, cocobolo, micarta, jigged bone etc. handles and charge less, then I'd be all over their knives.Now as for ease of sharpening, I'll simply say that anyone who's collecting knives can easily afford to buy a Spyderco Sharpmaker for significantly less than what you'd spend on a single knife and easily produce a sharp knives.

I've already bought 6 or 8 Great Eastern knives and I'm sure I’ll buy a few more, but it really irks me to think that if Great Eastern ever wakes up and begins to produce their knives with decent stainless blades that I'll probably have to re-buy them all over again, at least the ones that prove to be my favorites.

So, I'm with you, I hope somebody will some day start producing affordable traditional folders with quality stainless blades.

'Nuff said.

G.

-

-

Permalink Reply by Jack Haskins, Jr. on October 21, 2014 at 8:57

-

Is there a way to post a poll on this forum? A company needs to know what their customers would prefer and forums are a good way to get an idea. I'm retired now and use a knife less on a daily basis than I used to so edge retention is not as big an issue in my cutting needs. Still, I love having knives that under light-medium use don't get dull. They may loose the shaving edge but not the sharp, usable edge. Since my cutting needs aren't as demanding the traditional folders with non-super-steels perform fine. I also carry 2-4 knives almost all the time so I don't depend on one knife. I like a range of small knives for small jobs and larger hard-use knives for when they are needed.

As you said new sharpening tools or stones may be needed to sharpen some of the newer steels quickly. I got into a sharpening obsession also so I now have DMT diamond, Spyderco ceramic and Shapton glass bench stones. These stones will sharpen anything I've owned. Even ZDP-189 at 64-66 Rc. My first better steel was VG-10 and the old Arkansas stones I had wouldn't cut the steel. I'm sure it's because they were not clean. I didn't know how to keep stones working properly. I'd wipe most of the oil off and put them away. 20 years of that probably left them performing poorly.

I still love the traditional folders though and GEC seems to put out as good as any and better than most. GEC and Case are the only traditional's I've owned recently and I choose GEC hands down. I only have one GEC so far but I love it. I'm happy with 1095 on this type knife. I won't be using it to cut the occasional small limb I see in my yard. The EDC traditionals I carry just aren't built for that type of use. I've been looking at the farm & tool line and maybe a model of that group with a really nice edge holding blade would be appreciated. A stronger knife with a stronger steel? What's not to like? :) While I'd love to see different steels on a traditional folder I'm happy with 1095 for my needs. Using an extra-fine DMT stone alone I can do a few strokes to put a razor (almost) edge on it. With more aggressive stones you would need to take it easy I'm sure. That's another thing about edge retention. Shaprening ability. If an edge of any steel has a nice clean (no burrs) edge it should hold that edge longer under the same use than an edge that while it feels sharp right off the stones has microscopic burrs. During use these very hard to detect burrs can snap off leaving the edge cutting less effectively. I'm not an expert but it seems there are more things that contribute to edge retention than the steel alone.

Anyway, I'd love to see a line of super steel GEC's. Personally I'd opt for CPM-M4. In my experience this is one of the 2 or 3 I call favorites. It takes a supurb edge and holds it. It's considered a carbon or non-stainless steel but it doesn't corrode as fast as some of the other carbon steels. I almost never promise to buy a knife if it has a feature we discuss on forums but I think if GEC put out a model I like with M4 they would have one sale anyway. So they won't go COMPLETELY out of business. :)

When I bought the GEC I have now I made a list of qualifications. Beauty was one of them. I satisfied that with my GEC buckaroo. It also has the walk and talk I see mentioned in the videos. Sometimes when we want specific features in a knife we have to live with less in another area. My GEC is beautiful. It doesn't scare anyone either. :) I love this knife. I've even gotten a couple of looks from people when I use it. I read the expression as "nice looking knife". I like that. I haven't gotten the "OH MY GOD! A SERIAL KILLER!" look I get from some of the larger knives I carry. :) I'm beginning to ramble.

I am very happy with my GEC and will get more in the future. Yup, even with 1095. :) I try not to forget that just because there are newer steels with different (I don't like to say better) characteristics, some of the older, tried & true steels still get the job done. NOTE: I carry a DMT credit card size sharpener in case I need it. :) So there is an option for when a knife dulls a bit when away from home. With a good, small diamond stone all you need is about 30 seconds to bring a slightly dull edge back to cutting excellence. But if I let the edge get really dull it takes more time to get it sharp again of course. There's nothing like having great performing sharpening tools, just like a great performing knife.

Jack

Gregory Warren said:Jack, I couldn't agree with you more.

In the past few years I've been a collector of modern folders and tactical knives - mostly Spyderco's, Benchmade's, A.G. Russell's, with a few Mcustas, Lionsteels, Vipers, and Kershaws to round out the picture. And I can assure you that if, say, Spyderco came out with any knife in 1095 carbon steel, they wouldn't sell even one. I guess we've become steel snobs on the other side of the collector aisle.

But, really, when you consider that you can buy a ton of modern folders for less than $50, or even less than $30, all of which are made with steels which will outperform 1095 both in edge retention, and, they don't rust, it just makes one wonder what it's going to take to get the traditional folder makers to wake up and offer their wares with modern stainless blade steels.

You've got the Japanese steel makers like Hitachi along with Latrobe, Crucible, Carpenter, and Bohler making fantastic stainless blade steels so why can't we get these into the traditional folder world??

Thank goodness that Queen Cutlery (not Queen City) offers their knives in D2 steel which, with 11.5% chromium, is at least semi-stainless and is a good blade steel to boot. I also think that Queen represents one of the better values in the traditional market, but they just don't offer the variety of patterns that Great Eastern does.

I know that Schatt & Morgan's File & Wire series of knives are made with ATS-34 steel, and their Keystone series are made with 420 HC (which ain't all that great, but still better than 1095), but I've already collected all the patterns in these two lines that I'm interested in so now I'm faced with having to buy traditionals from Great Eastern in a steel which I consider to be distinctly inferior.

And as for Case knives which are made with "True Sharp" surgical stainless steel, the steel is so soft at an HRC of 54-57, that after a half dozen sharpenings, you've go no knife left - the steel is just that soft. Most people don't realize that "surgical stainless" knives are throw away knives that are disposed of after every surgery. So I would never consider buying a Case knife. They may be alright for collecting as “Safe Queens,” but I guess I'm more of a user than a collector, so I'll take a pass on Case knives.

I'm happy to see that Tuna Valley is using 154CM blade steel, but I'm not as yet so enamored of stag handles that I'm willing to pay extra $50 to $100 per knife for stag handles just to get a good blade steel. If Tuna would produce a line with less expensive ebony, cocobolo, micarta, jigged bone etc. handles and charge less, then I'd be all over their knives.Now as for ease of sharpening, I'll simply say that anyone who's collecting knives can easily afford to buy a Spyderco Sharpmaker for significantly less than what you'd spend on a single knife and easily produce a sharp knives.

I've already bought 6 or 8 Great Eastern knives and I'm sure I’ll buy a few more, but it really irks me to think that if Great Eastern ever wakes up and begins to produce their knives with decent stainless blades that I'll probably have to re-buy them all over again, at least the ones that prove to be my favorites.

So, I'm with you, I hope somebody will some day start producing affordable traditional folders with quality stainless blades.

'Nuff said.

G.

-

-

Permalink Reply by Jan Carter on October 21, 2014 at 9:26

-

Jack

There is a poll that can be e mbe dde d and used here. I a m on my w ay home and w ill send you the info whe n I ge t there

-

-

Permalink Reply by Jack Haskins, Jr. on October 21, 2014 at 10:00

-

When you get home is good. From the looks of your post you are either driving or intoxicated. :) Personally, I'd blame the keyboard. lol

Jack

Jan Carter said:Jack

There is a poll that can be e mbe dde d and used here. I a m on my w ay home and w ill send you the info whe n I ge t there

-

-

Permalink Reply by Jack Haskins, Jr. on January 4, 2015 at 14:55

-

Beautiful knife. I got a knife with a single wharncliffe blade for Christmas. Who cares if I bought it and wife was the only one surprised. :) I've carried it since and I've had mixed emotions about the blade. I'd say at first I didn't care for the wharncliffe as it wasn't the best shape IMO for most of the tasks I came across. OTOH, I've had some tasks that the skinny point was just the ticket for some jobs. The wharncliffe blade on my GEC is the standard shape (sheepsfoot I think) and while it does great when a straight edge is needed it won't get into the tight places like a pointier tip. The GEC though does have the longer clip point that will get into tighter places. So I think I'm covered. I guess there isn't one blade or edge shape that will serve every need. Do you know what that means???! We need to get another knife! LOL Again, that a great looking knife. Nothing better than a knife you are happy with performance and beauty.

Jack

-

-

Permalink Reply by Jan Carter on January 31, 2015 at 15:48

-

- ‹ Previous

- 1

- 2

- 3

- Next ›

Latest Activity

© 2026 Created by Jan Carter.

Powered by

![]()