iKnife Collector

The online community of knife collectors, A Knife Family Forged in Steel

Knife Repair, Modification, Restoration & Improvement

Information

This group is hosted by D ale, for knife enthusiasts who are interested in repairing, modifiying, restoring or improving knives, including fixed blades, folders and automatics of all types.

Members: 198

Latest Activity: Sep 29

Discussion Forum

An old Rapala (Marttiini) fillet knife

Started by Kevin D Sep 21. 0 Replies 2 Likes

I found this old fillet knife literally in pieces.The blade was bent. The tang was warped. The handle was too small (in my opinion). And the mechanical connection of the tang behind the handle was destroyed. The edge being useless was an obvious…Continue

Case Vault Release Razor rehandled in Mammoth Ivory

Started by Andy Larrison. Last reply by Andy Larrison Jun 12. 4 Replies 2 Likes

Had to try one out, so I sacrificed a jigged black synthetic handled razor and added some mammoth bark ivory that had some great character. First razor I've ever done, very easy pattern to work with.…Continue

Schrade 194OT Rehandle

Started by Andy Larrison Mar 13. 0 Replies 0 Likes

Had a customer reach out wanting me to barehead and add stag to this great Old Timer. Original handles and box can be seen in the pictures.…Continue

1972 Case Sodbuster Rehandle

Started by Andy Larrison. Last reply by J.J. Smith III Feb 25. 5 Replies 0 Likes

Recently removed the original black covers and replaced them with European red stag on this 1972 Case Sodbuster. Original covers can be seen lying to the left of the knife.…Continue

Buck 547 Skinner: Rehandle Project

Started by Andy Larrison. Last reply by Andy Larrison Feb 13. 4 Replies 2 Likes

I recently completed this rehandle project for a client. A Buck 547 skinner, the client is a huge fan of sambar stag, but it is getting hard to find stag the size of which we needed for this project. I should also add that he likes for his knives…Continue

Case Clasp Recover

Started by Andy Larrison Jan 30. 0 Replies 0 Likes

I recently was commissioned to replace the shrinking covers and add some filework on this Case Classic Clasp. Here are some before, during and after pictures of this project. I used inlace acrylester material for the new covers.…Continue

Comment Wall

Add a Comment

-

In Memoriam Comment by D ale on September 8, 2013 at 11:53 -

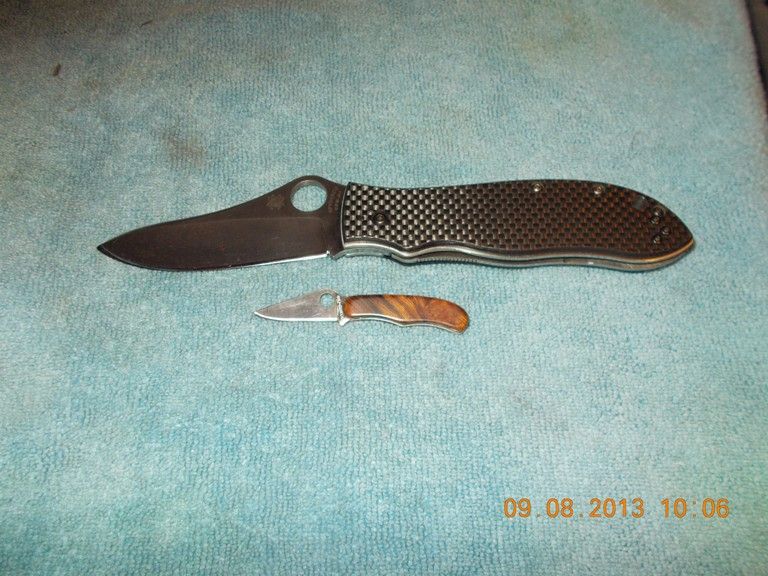

Nice job, Jack . Ironwood is some hard & pretty wood. The pattern resulting from the grain is sweet ..and.. if you drop it, the ironwood dents the floor.

-

Comment by Jack Haskins, Jr. on September 8, 2013 at 11:21

-

Comment by Jack Haskins, Jr. on September 8, 2013 at 11:19

-

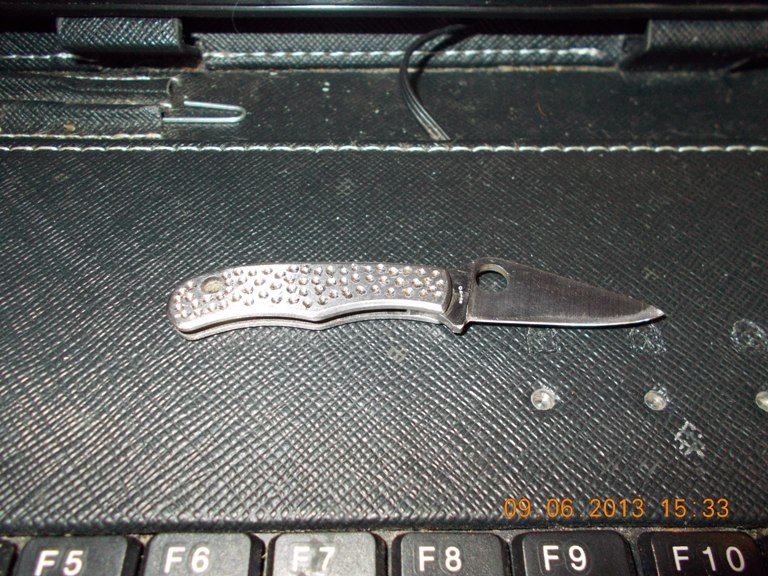

Comment by Jack Haskins, Jr. on August 18, 2013 at 21:52

-

Dale, I'll be looking at kits but I've also seen small sets (5-15) of slip joint knives on ebay that should provide practice knives. I'd like to get a few of the same model to use the good parts from each to make good knives. Well, usable anyway. It'll probably take me two weeks to develop the skill to create works of art. :) Ok, maybe three. lol

-

In Memoriam Comment by D ale on August 18, 2013 at 21:18 -

Knifekits.com has kits available .. a simple "screw parts together" kit can be had as low as $ 17 + shipping. A partial pin together kit (i.e. scales pre-attached) can be had for the same.

Blades are pre-tempered .. a little on the soft side for my preference .. one has a working knife upon assembly though .. a good learning experience.

..... still cheaper to buy a couple abused knives @ yard sales. Dis-assemble those & attempt re-assembly. Repeat until reassembly successful.

-

Featured Comment by Charles Sample on August 18, 2013 at 20:34 -

Jack, SMKW has some Rough Rider kits. They don't look to awful hard to put together and they are cheap. Might be good for practice.

-

Comment by Jack Haskins, Jr. on August 18, 2013 at 18:44

-

Oops. I meant to say "it is NOT a "put parts together" kit. Keyboard can't spell. lol

-

Comment by Jack Haskins, Jr. on August 18, 2013 at 18:41

-

I just looked for kits on usaknifemakers.com. They have several. I see a Gunstock 3.25" closed kit that looks interesting. But, it looks like it still needs to be ground, heat treated, fit and finished according to the description. So it's now just a "put parts together" kit. I'll have to call them to see if there is any aspect I can't do. I know I can't grind a blade. The picture looks like the blade comes cut to shape but no FFG or hollow grind or anything like that. If I tried to grind it I'd end up with a FFG, hollow and saber grind in different places on the same blade. lol

-

Comment by Jan Carter on August 18, 2013 at 17:43

-

Ron that is some cool information. There are so many ways to learn the mechanics of a knife these days. Buying a kit will help you understand how it all fits together

http://www.premiumknifesupply.com/servlet/the-259/Kit-S002-Osaka-Fo...

-

In Memoriam Comment by Robert Burris on August 14, 2013 at 10:14 -

Oh yea, Colonial, a user man's knife company.

White River Knives

Latest Activity

Featureddead_left_knife_guy replied to Doug Ritter's discussion Knife Rights Sues Minnesota over Unconstitutional Switchblade Ban

KnifeMakerAndy Larrison replied to Dennis Hibar's discussion A new iKC calendar and a new year of knives!

Visit Lee' s Cutlery

KNIFE AUCTIONS

KNIFE MAGAZINE!!!

JSR Sports!

Click to visit

© 2024 Created by Jan Carter.

Powered by

![]()

You need to be a member of Knife Repair, Modification, Restoration & Improvement to add comments!