On a nice spring day in 1960, our country school teacher, Mrs. Edith Novotny Nepper, led the whole school on an all-day field trip – to Clarkson, Nebraska. All smirking aside, it turned out to be one of the most interesting and memorable field trips that I experienced in all my school days. We toured a variety of interesting businesses, and learned about the inner workings of places that we knew only as customers or store fronts. In the morning we toured Elmer Makousky’s dairy on the east side of town and learned how milk was collected, processed, packaged, and distributed (milk was still delivered to the customers’ doorsteps in glass bottles in those days). At the Clarkson Hatchery and Farm Supply, we were told about commercial feeds and the business of chicken and egg production. At the offices of the Colfax County Press, we were greeted with the sights, sounds, and smells of the newspaper publishing business; at that time, they were still setting type with individual lead type letters, and we left that tour stop with a lead stamp of our name in the Press’ typefont. And sometime during that day, we drove up the hill on the west side of main street, walked over to a wooden garage/outbuilding, and were greeted by an old man who was arguably Clarkson’s most famous personage – Frank J. Richtig. Frank J. Richtig, a blacksmith turned car dealer turned knife maker, has the distinction of being the only person in Clarkson, and likely the only in Colfax County, to have been featured in Ripley’s Believe It or Not!

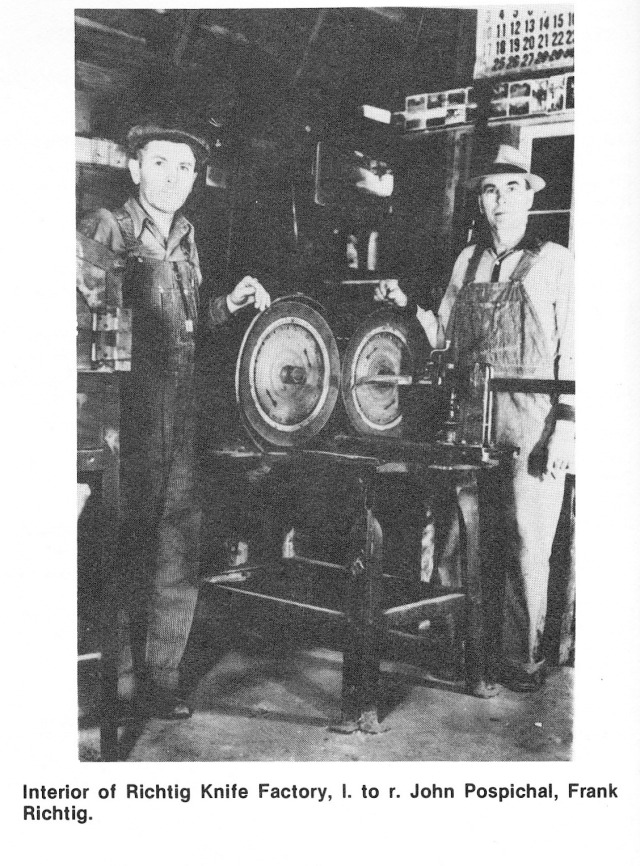

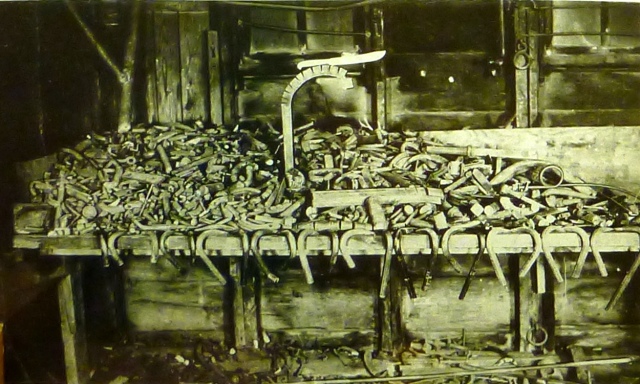

I remember very little of the tour of Richtig’s workshop; it didn’t look much different from the workshops in most farmer’s machine sheds. It was dark inside, the walls and shelves were covered with hammers, knives, saws, and other tools, and on the floor were piles of scrap metal. He probably told us about the process of forging steel, showed us how to heat it red hot in order to pound it into the desired shape. But what really caught our attention was when he performed his well-known feat – he held up one of his knives and, with a hammer, pounded the blade through a three-quarter-inch-thick strap of steel and cut it in two. He did this several times, then held up a piece of paper and sliced it like a razor with the knife that had just cut through steel. It seemed so impossible to us that we wondered whether it was some kind of trick. But it was no trick. Richtig was able to do this because many years earlier he had discovered a process for hardening steel that was truly revolutionary. A secret process that he took with him to his grave.

Frank J. Richtig was born on December 28, 1887. In 1906 he apprenticed to a blacksmith in Clarkson, Frank Koci. By 1908 he had gone into partnership with Joseph Walla (their first blacksmith shop was located on the site of the Dr. O’Neal’s medical office). Between 1910 and 1920, in addition to smithing, Richtig sold cars in partnership with V.L. Prazak; over the years they sold Dodge and Dort cars, and something called a Guaranty truck (“any make of car can be converted into a durable and guaranteed truck”).

Notice from the sign the original spelling of his name – Rychtig. This spelling was used around Clarkson into the 1920s.

During this time, Richtig began experimenting with the process of tempering steel, with the goal of creating knives that were so hard that they would rarely need sharpening. By the mid-1920s or early 1930s (the exact date is uncertain), he perfected the tempering process that resulted in knife blades so strong that they could “cut horse shoes into small pieces, as well as three-fourths inch crowbars, automobile axles, and even industrial steel locks, and yet undulled and without sharpening, still have blade enough left to cut paper into bits.” By 1935, production of the marvelous knives was in full swing. The October 17, 1935 issue of the Colfax County Press reported:

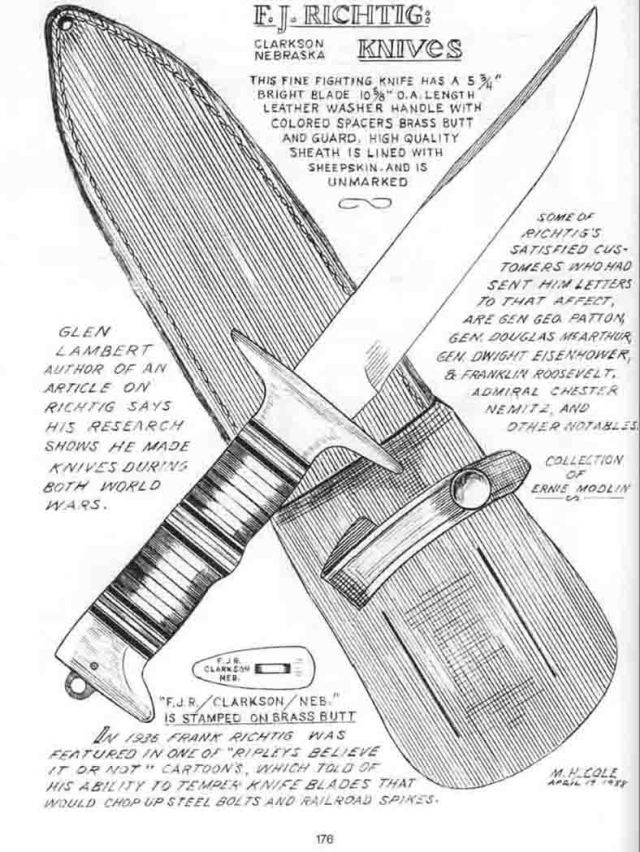

Richtig made a variety of kitchen and butcher knives, often with poured aluminum handles. He made a circular display rack to show the different types of knives he had for sale, and with a two-wheel trailer he took his products to county and state fairs, giving demonstrations of the unbelievable strength of his knife blades.

The Colfax County Press of September 16, 1937 reported that “Frank J. Richtig, Clarkson blacksmith, was on the fairground today demonstrating his steel knives that cut through three quarter inch cold steel. After driving a knife through a crow bar, chisel, or steel bit, Richtig will shave a piece of paper with its fine edge. Clarkson is a Bohemian district, and although Richtig is American born, he speaks with a heavy accent. But making knives, not talking, is his business in life, and he lets his traveling companion Julius Wacha, retired Clarkson general store owner, do part of the explaining. For 29 years he has made knives during odd moments when other blacksmithing was not pressing. Through long practice he developed his own technique for tempering the steel. Many offers have come from large steel concerns for him to join their companies and teach his secret to their men. But in Clarkson he has his home, his family, and there he prefers to stay. Through Colfax, Stanton, and Cuming counties Richtig is famous for sharpening plow shares, Wacha says, and in his time there he has worked on at least 60,000. Two years ago Richtig decided to extend the sales of his knives, so he began making the fairs, giving demonstrations. Most of the actual sales are mail order. The knives are not hard, Wacha explained. But they are so tempered that they will hold a razor edge.” (In addition to Julius Wacha, others who toured with Richtig to help with his demonstrations included W.J. Moore, Frank J. Svik, A.C. Fajman, George Bohacek, James Stransky, Marvin Teply, and Louis Faltys.)

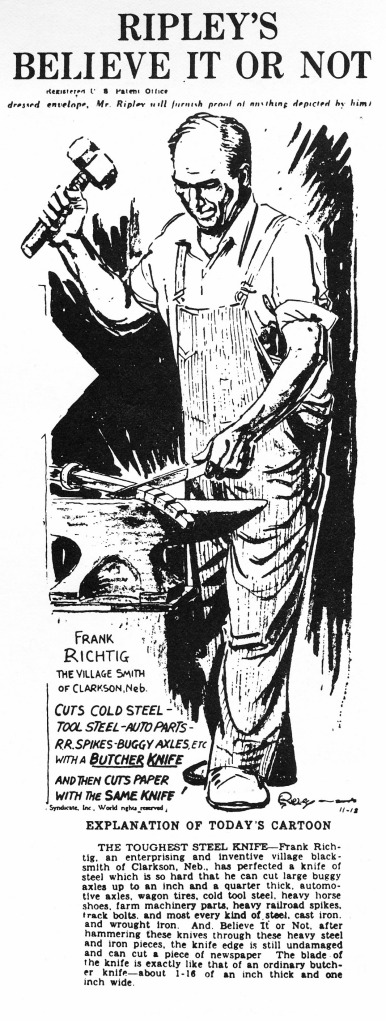

After he used one of his knives to cut off the hardened lock on a jail cell in Cedar Bluffs, Richtig drew the attention of the editors of Ripley’s Believe It or Not, who asked for information. A Clarkson artist, William Powolny, drew up a sketch and provided the text for the Ripley column, which appeared on November 18, 1936.

After the Ripley story, he became something of a celebrity, and the orders for his knives came pouring in. He received thank you letters for gift knives sent to such notables as President Franklin Delano Roosevelt, Gen. Dwight D. Eisenhower, Adm. Chester W. Nimitz, Gen. George Patton, and Gen. Douglas MacArthur. During World War II, he received many requests for combat knives. Unlike the kitchen knives, which featured smooth aluminum handles, the handles of the combat knives were comprised of discs of leather and red and yellow plastic. Richtig often gave free combat knives to local men who left for the service. Good examples of these combat knives easily bring over $4,000 among collectors.

Although Frank Richtig made large numbers of knives between 1935 and 1950 and continued to give demonstrations and make knives until his death, he always kept the tempering process that he had discovered a closely guarded secret. It is known that he did not forge his blades (like the legendary Japanese Samurai swords and the Arabs’ Damascus steel swords); rather, the hardness was achieved by grinding the blades from stock and relying on the subsequent heat treatment to develop their unique properties. Frank J. Richtig died on January 1, 1977, having told no one how to recreate the process. “A man is entitled to some secrets,” he once said, “and that’s mine.”

But scientific curiosity is not to be denied. Twenty three years after Frank Richtig’s death, two metallurgists from Lawrence Livermore National Laboratory in California published the results of their analysis of two of Richtig’s knife blades (Jeffrey Wadsworth and Donald Lesuer. 2000. The knives of Frank J. Richtig as featured in Ripley’s Believe It or Not. Materials Characterization: An International Journal on Materials Structure and Behavior. Volume 45, pages 315-326¬). The scientists subjected the Richtig blades to a battery of tests: measurements of hardness, chemical composition, tensile stress, and high magnification analyses of the steel’s microstructure. And for good measure, they used one of the Richtig knives to hammer through a 6-mm-diameter steel bar without damage to the blade (a test that caused a contemporary high-carbon steel kitchen knife to chip).

So, for those of you who have waited all your lives to learn the secret of the unbelievable hardness and enduring sharpness of Frank Richtig’s knives, here are Wadsworth and Lesuer’s conclusions: “Our best estimate of the Richtig secret recipe is as follows:

1. AISI 1090 or 1095 steel was used.

2. The steel was austenitized at a temperature just slightly above (e.g., 30 degrees C) the A1 temperature.

3. The steel was austempered at 300-400 degrees C.”

Or, in layman’s terms, Wadsworth and Lesuer deduced that the knives were made with ordinary carbon (1%) steel that was heated to nearly 1400 degrees F, rapidly cooled (in a second or less) to around 600 degrees F, and then held at that temperature for “tens of seconds.” Outside of the laboratory, they noted that such rapid cooling could be accomplished by quenching the thin blades into an isothermal salt or molten lead bath held at the appropriate temperature.

The scientists observed that “the use of an austempering process by Richtig is quite remarkable, since the process is generally recognized to have been introduced by Bain and Davenport in the 1930s. Since the Richtig knives, made with the secret heat-treating recipe, were famous by the 1930s, it is possible that Richtig discovered the austempering process before the two well-known metallurgists were generally recognized for discovering the process.”

Not a carnival trick, Frank Richtig’s knives were the real deal. And it appears that our Village Smithy was the first to discover the austempering process that made them so hard – before the later development and promotion of the process by professional metallurgists.

Metal pipes and rebar have never been safe since…